150Psi gasoline petrol fuel transfer pipe diesel line rubber oil hose

| Name | 150Psi fuel & diesel oil hose |

| Reference Standard | HG/T2540-93 |

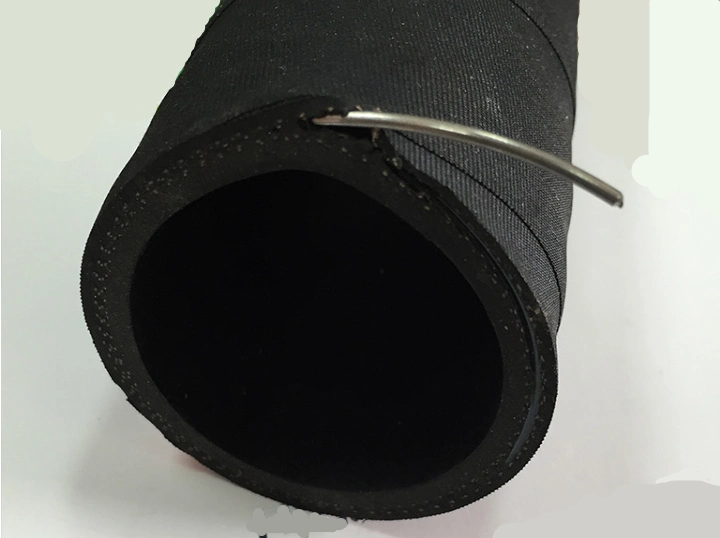

| Tube | Black, synthetic rubber |

| Reinforcement | high tensile textile cord with helix steel wire |

| cover | synthetic rubber, abrasion, weather and oil mist resistant |

| Working Temperature | -20ºC to +120ºC |

| Safety factor | 3 : 1 |

| Color available | black, grey, blue, yellow, red or as your order |

| Surface | smooth or wrapped finish |

| Character | anti static electricity, with copper wire |

| Application | handle petroleum products up to 50% aromatics |

Construction:

This hydraulic suction hose is composed of an inner tube of oil resistant synthetic rubber, a reinforcement consisting of a ply or plies of woven or braided textile fibers with a suitable spiral of body steel wire, and an oil and weather resistant synthetic rubber cover.

Advantages:

1.Selection of synthetic rubber hose with special made, with excellent oil resistance, heat resistance, anti-aging properties.

2. Hose for the high-pressure and superior pulse properties.

3. Hose combination of close, use soft, small deformation under pressure.

4. Hose has an excellent circumnutate resistance and fatigue resistance.

Specification:

| Inside Diameter | Outside Diameter | Working Pressure | Burst Pressure | Bending Radius | Weight | Length | |||||

| mm | inch | mm | inch | Psi | Bar | Psi | Bar | inch | mm | kg/m | m |

| 6 | 1/4 | 15 | 0.59 | 150 | 10 | 450 | 30 | 2 | 50 | 0.15 | 100 |

| 8 | 5/16 | 16 | 0.63 | 150 | 10 | 450 | 30 | 3.5 | 90 | 0.17 | 100 |

| 10 | 3/8 | 17 | 0.67 | 150 | 10 | 450 | 30 | 5.1 | 130 | 0.25 | 100 |

| 19 | 3/4 | 29 | 1.14 | 150 | 10 | 450 | 30 | 9.4 | 240 | 0.6 | 100 |

| 22 | 7/8 | 32 | 1.26 | 150 | 10 | 450 | 30 | 11 | 280 | 0.68 | 100 |

| 25 | 1 | 37 | 1.45 | 150 | 10 | 450 | 30 | 14.8 | 375 | 0.93 | 100 |

| 32 | 1 1/4 | 44 | 1.7 | 150 | 10 | 450 | 30 | 16.5 | 420 | 1.25 | 60 |

| 38 | 1 1/2 | 51 | 2 | 150 | 10 | 450 | 30 | 19.7 | 500 | 1.47 | 60 |

| 51 | 2 | 65 | 2.5 | 150 | 10 | 450 | 30 | 24.8 | 630 | 1.92 | 60 |

| 64 | 2 1/2 | 79 | 3.1 | 150 | 10 | 450 | 30 | 37.8 | 960 | 2.56 | 60 |

| 76 | 3 | 92 | 3.6 | 150 | 10 | 450 | 30 | 44.9 | 1140 | 2.96 | 60 |

| 90 | 3 1/2 | 106 | 4.2 | 150 | 10 | 450 | 30 | 53.1 | 1350 | 3.68 | 60 |

| 102 | 4 | 120 | 4.7 | 150 | 10 | 450 | 30 | 60.2 | 1530 | 4.22 | 60 |

Product Process:

1. we have a strong sales and service team of more than 15people, all of them have more than five years experiences in foreign trade, and you can get the most professional services to work with us.

2. we have advanced production facilities, including 10 high-speed fiber braid machines,12 high-speed steel wire braid machines, 2 steel wire spiral production line. we have adopted Italy VP Production line for Industrial hose and Maillefer extrusion line from Switzerland

3. we have strong quality control system, we have advanced laboratory. Before mass production, we test each batch raw material. After production, we test each hose to guarantee 100% qualification.

It is mainly used for Mine hydraulic support ,oilfield exploitation ,object construction ,lifting transport ,metallurgic forging ,mine equipment, ship, injection molding machinery, agricultural machinery , all kinds of machine tools and various industrial sectors mechanization and automation in the hydraulic system of conveying with a certain pressure(high pressure) and the temperature of the oil-based(such as mineral oil, soluble oil, hydraulic oil, fuel oil and lubricants) and water-based liquid (such as Emulsion, the oil-water emulsion, water) and liquid transmission used.

Related Product:

Contact Us:

QINGDAO EASTOP PLASTIC PRODUCT CO., LTD

Address: 2223 Building C, VANKE Center, Fuzhou Road, Qingdao, Shandong, China (Mainland)

Tel: +86-532-83860726